In the realm of waste management, where efficiency and safety are paramount, hot melt strapping has emerged as a revolutionary solution for bundling and securing various types of waste materials. This innovative packaging technique not only streamlines the waste disposal process but also ensures the stability and integrity of waste bundles during transportation and storage. This article delves into the advantages of hot melt strapping in the context of waste bundling, highlighting its unique features, applications, and overall impact on the waste management industry.

Waste management is a critical aspect of modern society, and efficient bundling of waste materials is essential for maintaining cleanliness, preventing litter, and ensuring the safe transportation of these materials to designated disposal sites. Traditional methods of waste bundling, such as using ropes or tape, often prove to be ineffective or labor-intensive. In contrast, hot melt strapping offers a faster, stronger, and more reliable alternative.

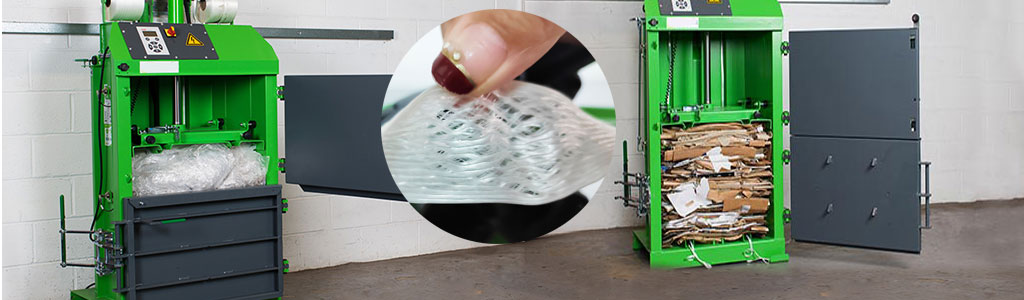

Hot melt strapping, also known as hot melt textile strap, utilizes a heated adhesive that melts upon application and then cools to form a strong, flexible bond. This type of strapping is available in various widths and thicknesses, making it suitable for a wide range of bundling applications. Its unique properties, including high strength, water resistance, and durability, make it an ideal choice for waste bundling.

One of the primary advantages of hot melt strapping in waste bundling is its ability to provide superior security and stability. The strong adhesive bond created by the heated adhesive ensures that waste bundles remain intact, even during transportation over rough roads or during handling by heavy machinery. This reduced risk of bundle breakage translates into fewer spillages and safer working environments.

Compared to traditional methods, hot melt strapping significantly reduces the time and labor required for waste bundling. The automated application process ensures quick and consistent bonding, eliminating the need for manual tying or taping. This increased efficiency allows waste management teams to handle larger volumes of waste with ease, thereby optimizing their workflow and reducing overall costs.

Hot melt strapping is incredibly versatile, making it suitable for bundling a wide range of waste materials. From lightweight paper and cardboard to heavy-duty metal scraps and plastic waste, hot melt strapping can handle it all. Its flexibility in terms of width and thickness allows for precise adjustment to meet the specific requirements of different waste types, ensuring optimal bundling performance.

In the context of waste management, hot melt strapping has found numerous applications. For instance, it is commonly used in recycling centers to bundle recyclable materials such as paper, cardboard, plastic bottles, and aluminum cans. This helps to keep the materials organized and prevents contamination during transportation to recycling facilities.

Similarly, hot melt strapping is employed in construction sites to bundle construction waste, including wood scraps, metal debris, and packaging materials. Its high strength and durability ensure that these bundles remain intact, reducing the risk of debris scattering and potential hazards to workers and the surrounding environment.

Hot melt strapping has revolutionized the way waste is bundled and transported, offering numerous advantages over traditional methods. Its superior security and stability, time and labor efficiency, environmental sustainability, and versatility in application make it an ideal choice for waste management professionals. As the waste management industry continues to evolve, hot melt strapping will play an increasingly important role in ensuring the efficient and safe disposal of waste materials.

In conclusion, the adoption of hot melt strapping in waste bundling is a testament to the innovative solutions being developed to address the challenges of modern waste management. By harnessing the power of this innovative technology, we can create cleaner, safer, and more sustainable communities for generations to come.