Introduction

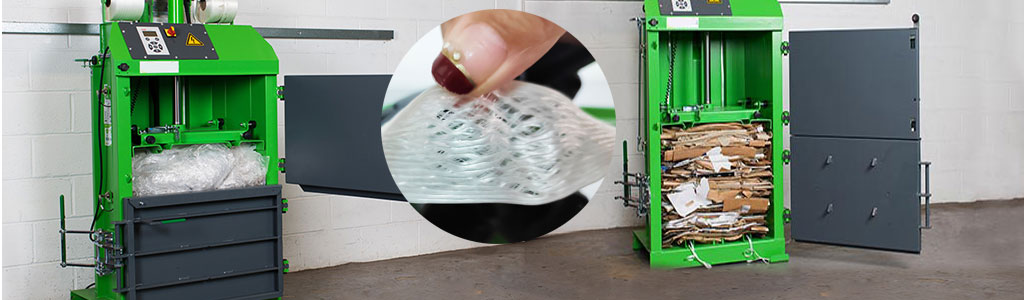

Baling press strap in cardboard bundling is a method of packaging and transportation that utilizes the strength of press-strapped cardboard boxes to secure and protect goods during shipping and handling. This technique is widely used in various industries, from retail to logistics, to ensure the safety and integrity of products during transit. This article aims to provide a comprehensive guide to baling press strap in cardboard bundling, covering its benefits, applications, and best practices.

Benefits of Baling Press Strap in Cardboard Bundling

1. Enhanced protection: Baling press straps provide additional strength and support to cardboard boxes, ensuring that the contents within are protected from damage during transportation.

2. Improved stacking ability: The use of press straps enables boxes to be stacked more securely, reducing the risk of collapse and damage to the contents.

3. Space efficiency: By bundling multiple boxes together, baling press strap in cardboard bundling allows for more efficient use of space during storage and transportation.

4. Cost-effectiveness: Compared to other packaging methods, baling press strap in cardboard bundling can be a more cost-effective solution, as it reduces the need for additional packaging materials and minimizes the risk of product damage.

Applications of Baling Press Strap in Cardboard Bundling

1. Retail: Retailers often use baling press strap in cardboard bundling to securely package and transport goods from suppliers to their stores.

2. Logistics: Logistics companies utilize baling press strap in cardboard bundling to efficiently transport goods from one location to another.

3. Manufacturing: Manufacturers can use this method to safely package and transport their products to customers or distributors.

Best Practices for Baling Press Strap in Cardboard Bundling

1. Proper box selection: Ensure that the cardboard boxes used for baling press strap in cardboard bundling are strong enough to withstand the strain of the press strap and the weight of the contents.

2. Correct strap tension: Adjust the tension of the press strap according to the weight of the contents and the number of boxes in the bundle.

3. Proper strap placement: Ensure that the press strap is placed in a location that maximizes support and minimizes the risk of damage to the box or its contents.

4. Regular inspection: Regularly inspect bundles for any signs of strain or damage to the press strap or cardboard boxes, and make any necessary adjustments.

Conclusion

Baling press strap in cardboard bundling is an effective and versatile packaging and transportation method that provides enhanced protection for products during shipping and handling. By understanding its benefits, applications, and best practices, businesses can ensure the safety and integrity of their goods throughout the supply chain.

Remember, the key to successful baling press strap in cardboard bundling is selecting the right cardboard boxes, adjusting the tension of the press strap correctly, placing the strap in the optimal location, and regularly inspecting the bundles for any signs of damage or strain. By following these guidelines, businesses can enjoy the many benefits of baling press strap in cardboard bundling while minimizing the risk of product damage during transportation.