In the ever-evolving landscape of waste management, the role of waste balers and strapping cannot be overstated. These seemingly simple tools play a crucial part in the efficient handling, transportation, and disposal of various types of waste, ranging from plastics to cardboard to metal scrap. Understanding the workings and benefits of waste balers and strapping is essential for any business or organization looking to reduce its environmental impact and optimize its waste management processes.

Introduction to Waste Balers

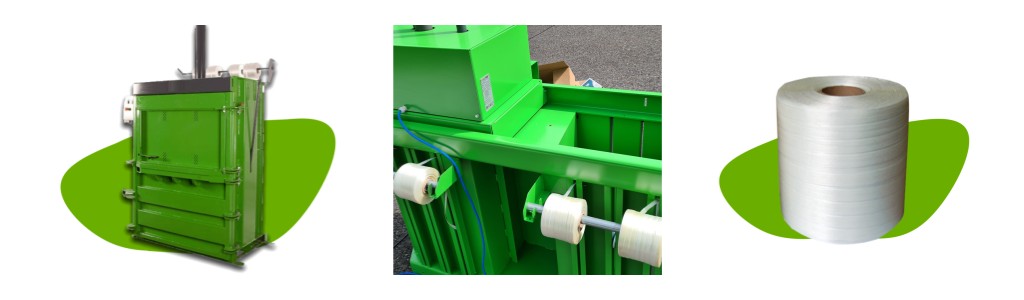

Waste balers, also known as waste compactors, are machines used to compress and bundle waste materials into dense, manageable blocks or "bales." These balers come in a variety of sizes and configurations, depending on the specific needs of the application. Some are designed for small-scale operations, while others are industrial-sized machines capable of handling large volumes of waste.

The primary function of a waste baler is to reduce the volume of waste, making it easier to transport and store. By compressing the waste, balers also help reduce the number of trips required for disposal, thereby saving on transportation costs and reducing the environmental impact of frequent trips.

Types of Waste Balers

There are several types of waste balers commonly used in waste management, including:

1.Vertical Balers: These balers have a vertical compression chamber and are typically used for high-volume waste applications. They are often found in manufacturing facilities and recycling centers.

2.Horizontal Balers: Horizontal balers have a horizontal compression chamber and are suitable for handling bulky items or large volumes of loose waste. They are commonly used in warehouses and distribution centers.

3.Auto-Tie Balers: These balers automatically tie the compressed waste using straps or wires, further reducing the need for manual handling.

The Role of Strapping in Waste Management

Strapping, in the context of waste management, refers to the use of straps or ties to secure compressed waste bales. This step is crucial in ensuring the integrity of the bale during transportation and storage. Without proper strapping, the bale could potentially become松散 (loosened) or even disintegrate, leading to waste spillage and increased handling costs.

Strapping materials vary depending on the type of waste and the intended use of the bale. Common strapping materials include:

1.Polyester Straps: Polyester straps are strong and durable, making them a popular choice for securing heavy waste bales. They are also resistant to chemicals and abrasion.

2.Steel Straps: Steel straps are ideal for securing extremely heavy or bulky waste bales. They offer unparalleled strength and durability but can be more difficult to handle and install.

3.Plastic Straps: Plastic straps are lightweight and easy to use, but they may not offer the same level of strength as polyester or steel straps. However, they are suitable for lighter-duty applications.

The Benefits of Using Waste Balers and Strapping

The use of waste balers and strapping in waste management brings numerous benefits, including:

1.Reduced Transportation Costs: By compressing waste into dense bales, balers significantly reduce the volume of waste that needs to be transported. This, in turn, reduces the number of trips required for disposal, saving on fuel costs and vehicle wear and tear.

2.Optimized Storage Space: Compressed waste bales occupy far less space than loose waste, allowing businesses and organizations to maximize their storage capacity. This is especially beneficial for facilities with limited storage space.

3.Reduced Environmental Impact: By reducing the number of trips required for waste disposal, balers and strapping help lower the overall environmental impact of waste management operations. This includes reducing emissions from transportation vehicles and minimizing the amount of waste sent to landfills or incinerators.

4.Improved Safety: Properly secured waste bales are less likely to become松散 (loosened) or disintegrate during transportation, reducing the risk of waste spillage and potential hazards to workers and the environment.

5.Increased Recycling Efficiency: Compressed waste bales are easier to sort and process for recycling, leading to higher recycling rates and reduced waste sent to landfills.

In conclusion, waste balers and strapping play an integral role in modern waste management practices. By compressing and securing waste into dense, manageable bales, these tools help reduce transportation costs, optimize storage space, minimize environmental impact, improve safety, and increase recycling efficiency. As we continue to face challenges in waste management, the importance of these seemingly simple tools becomes even more apparent.