Introduction

Waste baling straps have evolved significantly over the past few decades, becoming an essential component in the waste management and recycling industry. With increasing environmental concerns and stringent regulations, it is crucial to understand the development and sustainability aspects of waste baling straps. This article aims to provide an in-depth analysis of the evolution, types, and sustainability features of waste baling straps.

The Evolution of Waste Baling Straps

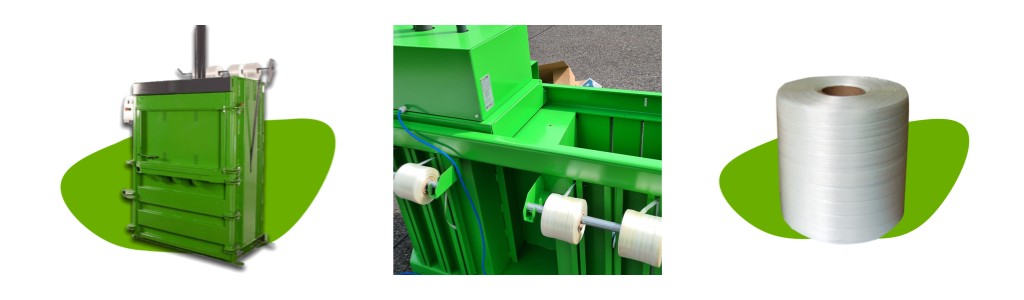

Traditionally, waste baling straps were made from natural fibers like hemp and cotton. However, with the advent of synthetic materials in the 1960s, polypropylene (PP) and polyethylene (PE) straps emerged as more durable and cost-effective alternatives. These synthetic straps are now widely used for baling various waste materials, including paper, plastic, and metal.

Types of Waste Baling Straps

1. Polypropylene (PP) Straps: PP straps are known for their high tensile strength, low moisture absorption, and resistance to ultraviolet (UV) light. They are ideal for outdoor applications and long-term storage.

2. Polyethylene (PE) Straps: PE straps offer excellent flexibility

3. Composite Straps: Combining the benefits of PP and PE, composite straps provide enhanced strength and flexibility. These straps are suitable for heavy-duty applications and challenging environments.

4. Biodegradable Straps: Made from renewable resources like cornstarch and bamboo fibers, biodegradable straps are a sustainable alternative to traditional synthetic straps. They decompose naturally in landfills, reducing environmental impact.

Sustainability Features of Waste Baling Straps

As environmental concerns grow, waste baling strap manufacturers are focusing on developing sustainable products. Some key sustainability features include:

1. Recyclability: Many waste baling straps are recyclable, allowing them to be reprocessed into new straps or other products.

2. Biodegradability: Biodegradable straps made from natural materials break down in landfills, minimizing pollution and greenhouse gas emissions.

3. Reduced Energy Consumption: Manufacturers are constantly improving production processes to reduce energy consumption and carbon emissions associated with waste baling strap production.

4. Use of Recycled Materials: Some waste baling straps are made from recycled plastics, reducing the demand for virgin materials and lowering overall environmental impact.

Conclusion

Waste baling straps have evolved significantly over the past few decades, with a focus on sustainability and environmental responsibility. As we strive for a greener future, it is crucial to choose waste baling straps that prioritize recyclability, biodegradability, and reduced energy consumption. By doing so, we can contribute to a more sustainable waste management and recycling industry.