In the realm of industrial operations, the efficient handling and packaging of materials are paramount to maintaining production lines, reducing costs, and ensuring safety. Among the myriad of tools and equipment that facilitate these processes, baling press straps stand out as a crucial component, indispensable for securing and transporting goods securely. This article delves into the significance of baling press straps, their unique features, applications across various industries, as well as the advancements that have transformed their efficacy and durability.

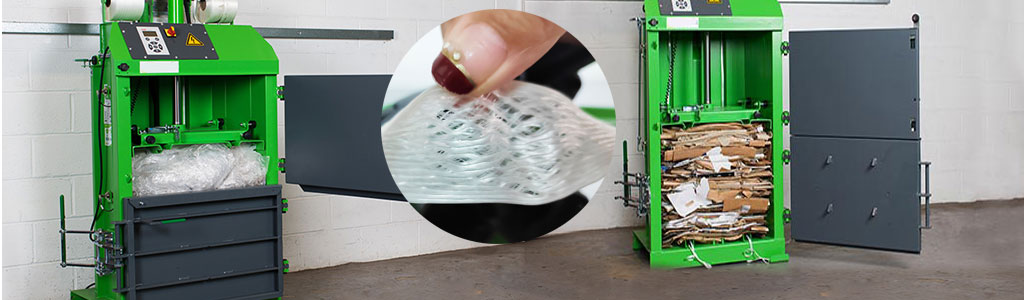

Baling press straps, also commonly referred to as compression straps or bundling straps, are designed to apply substantial force around a compressed bundle of materials, securing it for transport or storage. These straps are often made from high-tensile materials such as polyester, nylon, or polypropylene, which are chosen for their strength, durability, and resistance to moisture and chemicals. The versatility of baling press straps makes them an essential part of many industrial processes, ranging from recycling facilities to agriculture, textiles, and even the automotive industry.

One of the defining features of baling press straps is their incredible strength-to-weight ratio. This allows them to securely bind even the heaviest loads without breaking or deforming, ensuring that goods arrive at their destination intact. Their durability ensures that they can withstand repeated use and exposure to harsh conditions, making them a cost-effective long-term solution.

Another crucial aspect of baling press straps is their adjustability. Most modern designs incorporate tensioning mechanisms or ratchet buckles, which allow operators to tighten the straps to the exact required level of compression. This flexibility ensures that no matter the size or shape of the bundle, it can be securely bound without sacrificing efficiency or safety.

Safety is a top priority in any industrial setting, and baling press straps contribute significantly to this end. By securely holding materials in place, they prevent shifting during transport, which could lead to accidents or damage. Additionally, some advanced designs incorporate reflective strips or color coding for better visibility, further enhancing workplace safety.

In recycling facilities, baling press straps are invaluable for compressing and securing recycled materials like cardboard, plastics, and metals into manageable bundles. This not only saves space but also simplifies the transportation process, reducing transportation costs and environmental impact.

Farmers and agricultural businesses rely on baling press straps to secure hay, straw, and other forage crops into tight, compact bales. This ensures that livestock have a reliable and nutritious food source throughout the year, while also facilitating efficient storage and transportation.

The textile and apparel industries often use baling press straps to bundle fabric rolls, yarn bales, and completed garments. These straps ensure that materials are securely packed for shipping, minimizing damage during transit and optimizing warehouse storage.

Within the automotive sector, baling press straps find application in the transportation of auto parts, scrap metal, and even complete vehicles. They provide a robust and reliable method of securing heavy loads, ensuring that vehicles and components arrive at their destination in pristine condition.

Over the years, technological advancements have significantly improved the performance and lifespan of baling press straps. Materials science has led to the development of stronger, lighter, and more environmentally friendly materials. For instance, biodegradable and recyclable strap options are gaining popularity, aligning with industry-wide sustainability efforts.

Furthermore, advancements in automation and robotics have made it easier to apply and tension straps quickly and efficiently. This not only enhances productivity but also reduces the risk of injuries associated with manual handling.

In conclusion, baling press straps are a vital component of efficient material handling and packaging across a wide range of industries. Their strength, durability, adjustability, and safety enhancements make them indispensable for securing and transporting goods securely. As technology continues to evolve, we can expect to see even more innovations in the design and materials used for baling press straps, further enhancing their effectiveness and sustainability. For any industrial operation looking to optimize its packaging and transportation processes, investing in high-quality baling press straps is a decision that pays dividends in the long run.