In the fast-paced world of logistics and material handling, packaging efficiency is paramount. From warehousing operations to recycling facilities, the ability to compress, secure, and transport materials effectively can significantly impact operational costs, safety standards, and overall productivity. Among the myriad of tools and technologies employed to achieve these objectives, high-quality baler press straps stand out as a critical component in enhancing packaging efficiency. This article delves into the importance of baler press straps, their role in optimizing packaging processes, and the benefits of investing in superior-grade products.

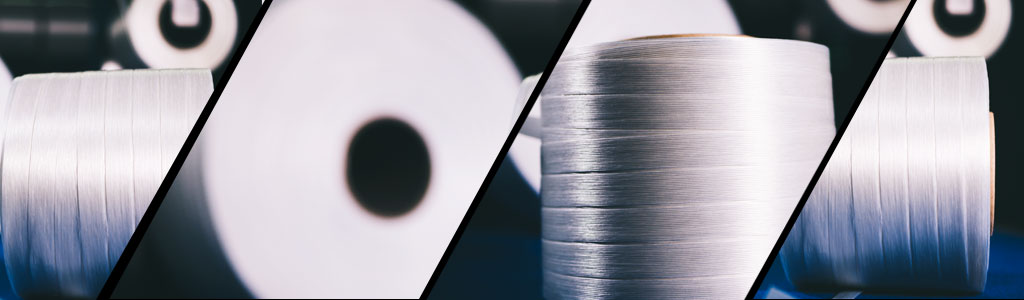

Baler press straps are specifically designed for use with baling presses, industrial machines tasked with compressing various materials into compact, manageable bundles. These materials can range from recyclable waste like cardboard, paper, and plastic to scrap metals and even certain types of agricultural waste. The straps themselves are constructed from robust, high-tensile strength materials, typically polyester or nylon, which are engineered to withstand the immense pressures exerted by the baling process.

Their primary function is to securely hold the compressed materials together, ensuring they remain intact and do not shift or become damaged during handling, transportation, and storage. Baler press straps often feature easy-to-use locking mechanisms, such as buckles or hooks, which allow operators to quickly and efficiently secure the straps around the compressed bundles. This not only facilitates faster packaging but also reduces the risk of human error and associated safety hazards.

The quality of the baler press strap can have a profound impact on packaging efficiency and overall operational performance. Here are some key benefits of investing in high-quality straps:

1.Durability and Strength: Superior-grade straps are designed to withstand repeated use and the rigorous conditions of the baling process. They are less likely to snap or degrade over time, reducing the frequency of replacements and minimizing downtime. This not only saves on replacement costs but also ensures consistent packaging quality and reliability.

2.Enhanced Safety: High-quality baler press straps are less prone to failure, which significantly reduces the risk of accidents caused by broken straps or unsecured loads. This is particularly important in environments where workers are frequently exposed to heavy machinery and compressed materials.

3.Improved Load Stability: Strong and secure straps contribute to better load stability, preventing compressed bundles from shifting or collapsing during transportation. This not only protects the materials within but also minimizes the risk of damage to surrounding cargo or transportation equipment.

4.Operational Efficiency: High-quality straps that are easy to apply and remove can significantly speed up packaging processes. This leads to increased throughput, reduced labor costs, and improved overall operational efficiency.

5.Environmental Impact: Investing in durable, reusable straps helps reduce waste and environmental footprint. Unlike disposable alternatives, high-quality baler press straps can be used multiple times, contributing to more sustainable packaging practices.

When selecting baler press straps, it's crucial to consider the specific needs of your operation. Factors such as the type of materials being compressed, the size and weight of the loads, and the environmental conditions in which the straps will be used should all be taken into account.

For instance, operations dealing with heavy scrap metals may require straps with even higher tensile strength than those used for lighter materials like cardboard. Similarly, facilities located in humid or corrosive environments may benefit from straps coated with protective materials to resist degradation.

Moreover, it's important to source straps from reputable manufacturers who can provide detailed specifications, including tensile strength, elongation, and material composition. This ensures that the straps meet the safety and performance standards required for your application.

In summary, high-quality baler press straps are indispensable for enhancing packaging efficiency in a wide range of industrial settings. Their durability, strength, and ease of use contribute to faster, safer, and more cost-effective packaging processes. By investing in superior-grade straps, operations can significantly improve load stability, reduce downtime, and minimize environmental impact. Ultimately, the choice of baler press strap is a critical decision that can have a lasting impact on operational performance and overall business success.

As the logistics and recycling industries continue to evolve, the role of baler press straps will become even more critical. By staying informed about the latest advancements in strap technology and material science, operations can stay ahead of the curve, ensuring their packaging processes remain efficient, safe, and sustainable.