In the world of logistics and material handling, the need for reliable and durable strapping solutions is paramount. Whether you're dealing with agricultural produce, industrial materials, or waste management, the ability to securely compact and transport loads is crucial. Among the various strapping options available, bale strapping stands out as a robust and versatile solution, particularly when it comes to compacting bales and awkward loads.

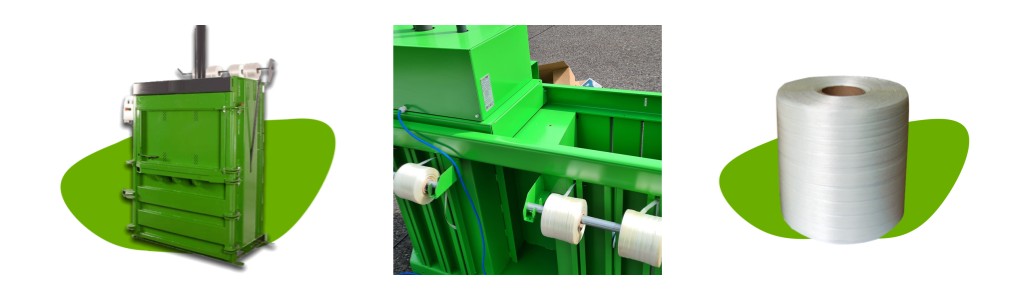

Bale strapping, also known as baling tape or bale press strap, is a specialized type of strapping designed for use in compacting and securing loads. It is made from a strong, durable material that can withstand the rigors of transportation and handling. Unlike traditional strapping materials, bale strapping is specifically engineered to be tear-resistant and fray-resistant, ensuring that it maintains its integrity throughout the entire process.

One of the key advantages of bale strapping is its versatility. It can be used in a wide range of applications, from compacting agricultural bales to securing industrial materials and waste. Whether you're dealing with large, bulky loads or awkward, irregular shapes, bale strapping can be tailored to fit your needs.

In agricultural settings, bale strapping is commonly used to compress hay, straw, and other types of forage into dense, manageable bales. This not only makes transportation and storage more efficient but also helps to preserve the quality of the forage by reducing exposure to air and moisture. Bale strapping is also used in the waste management industry to compact and secure waste materials, making them easier to transport and dispose of.

There are several benefits to using bale strapping, including:

1.Strength and Durability: Bale strapping is made from high-quality materials that are designed to withstand the rigors of transportation and handling. It is tear-resistant and fray-resistant, ensuring that it maintains its integrity throughout the entire process.

2.Ease of Use: Bale strapping can be easily applied by hand or using a baler or waste compactor. This makes it a convenient and efficient solution for a wide range of applications.

3.Customizability: Bale strapping can be tailored to fit your specific needs. Whether you need a specific width, length, or material, bale strapping can be customized to meet your requirements.

4.Re-tensionability: Unlike some other strapping materials, bale strapping can be re-tensioned if necessary. This means that if the load shifts or settles during transportation, you can easily adjust the strapping to maintain a secure fit.

When using bale strapping, it's important to follow best practices to ensure the best results. Here are some tips for using bale strapping effectively:

1.Choose the Right Material: Depending on your specific needs, you may need to choose a different type of bale strapping. For example, if you're dealing with particularly heavy or abrasive loads, you may need to opt for a thicker or more durable material.

2.Apply Even Pressure: When applying bale strapping, it's important to apply even pressure to ensure a secure fit. This means that you should avoid over-tightening or under-tightening the strapping, as this can compromise its effectiveness.

3.Use Heavy-Duty Steel Buckles and Tensioning Tools: To further enhance the security of your loads, consider using heavy-duty steel buckles and a basic tensioning tool. These accessories can help to distribute the pressure more evenly and provide additional support.

4.Inspect Regularly: Regularly inspecting your bale strapping for signs of wear and tear is essential for maintaining its effectiveness. If you notice any damage or wear, it's important to replace the strapping immediately to avoid potential safety hazards.

As the logistics and material handling industries continue to evolve, so too will the need for reliable and durable strapping solutions. Bale strapping is poised to play a key role in this evolution, thanks to its robust design and versatility. With advancements in materials and manufacturing processes, we can expect to see even more innovative and effective bale strapping solutions in the future.

In conclusion, bale strapping is a robust and versatile solution for compacting bales and awkward loads. Its strength, durability, and ease of use make it an ideal choice for a wide range of applications, from agriculture to waste management. By following best practices and regularly inspecting your bale strapping, you can ensure that your loads remain secure and safe throughout the entire transportation and handling process. As the industry continues to evolve, we can expect to see even more innovative and effective bale strapping solutions in the future, making it an essential tool for anyone working in the logistics and material handling industries.